Revealing details for the first time this November 2023 at the international Formnext manufacturing and tech expo in Frankfurt, Germany, Renishaw has unveiled its revolutionary new technology which enables manufacturers to cut 3D printing time in half, without sacrificing on quality.

The software, which has been in development for years, allows the users of 3D printers for metal component production — also known as metal additive manufacturing (AM) systems — to significantly reduce their build time by up to 50 per cent, with no impact on part quality.

This patented monitoring technology saves manufacturing processes — which can typically involve the building of components with thousands of layers — tens of hours of build time, offering a cost-effective, high-quality method that's never been seen before.

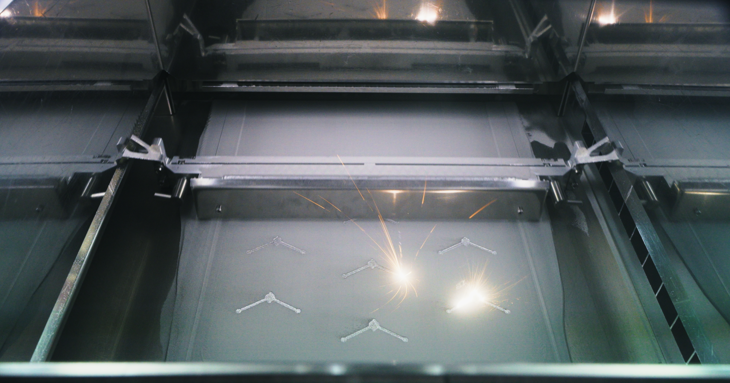

The advanced software, which Renishaw has called TEMPUS, works by instructing different tools to work at the same time, reading algorithms to sequence the data.

Louise Callanan, director of additive manufacturing at Renishaw, said: 'Reducing cost per part is critical to the wider adoption of AM technology. The dominant contributing factor to part cost for most components today is the time spent building the part on the machine itself. Reducing the amount of machine time per part, therefore, results in more cost-effective production.

'That’s why we’re excited to bring TEMPUS technology to the market. We believe the time and cost savings will open AM up to mass production applications where the technology would previously have been unviable. These innovations will deliver crucial productivity gains for AM users who want full-scale production at the lowest cost per part.'

The Wotton-under-Edge headquartered business brings its latest development to the industry in a year that has seen 50th-year celebrations for the company, an outstanding contribution award for its co-founder Sir David McMurtry and exciting new development plans for McMurtry's private company, McMurtry Automotive.